According to Shop! 30% of retailers say they plan to spend more in 2017 on store fixtures and millwork.

KDM just made accomplishing those plans more efficient.

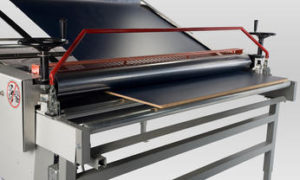

KDM installs new HMT Automated Advantage Plus Laminator

KDM POP Solutions Group has installed a new HMT Automated Advantage Plus Laminator at its KDM Retail Environment facility in Cincinnati, OH. The new machinery eliminates dry time, clean up, & harsh chemicals when applying laminates to substrates allowing for immediate fabrication of custom store fixtures. The cost-effective solution uses an eco-friendly, high performance hot melt film adhesive that is ideal for a wide variety of sheet and roll stock laminates from 2” to 61” wide by any length.

“Prior to this purchase, we were hand laminating sheets in assembly. This new, automated equipment provides the ability to pre-laminate required materials before milling, completely eliminating the manual process and any necessary dry times”, said Jim Brownley, General Manager.

KDM: Laminated store fixtures for Fast Casual Restaurant chain interiors