UV Flatbed Printer■

Most modern businesses will need large-format printing at some point. Whether you need promotional materials or other kinds of media, a UV flatbed printer might be right for you.

UV printing features multiple advantages over traditional ink printing, and KDM offers print-on-demand services so you can maximize your marketing efforts. Our innovative print solutions will allow your business to expand its reach and market smarter.

Our printing services can provide reliable and consistent marketing materials, so brands can better adapt strategies to local competition and trends.

What Is UV Flatbed Printing?

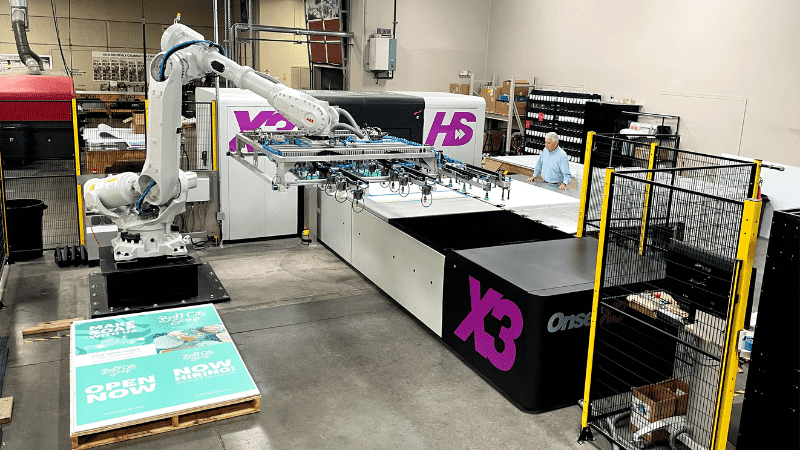

A flatbed UV printer is a special kind of printing tool that uses non-contact printing to reproduce images on flat surfaces, including packaging. A UV flatbed printer uses UV-sensitive ink that has a short curing time. Old flatbed printers used a mercury lamp, but modern flatbeds use a LED UV light to cure ink quickly.

UV printers are known for their high-speed print process and high image quality. UV inks cure quickly, so you can use the print immediately after you create it. UV flatbed printing is popular among customers due to its versatility, energy efficiency, and printing quality.

UV Flatbed Printer Features■

UV flatbed and other large-format flatbed printers have a lot of capabilities that make them a higher-quality method. UV flatbed capabilities include:

■ Large/small graphics ■ Second-surface printing

■ Rigid and flexible materials (e.g., acrylic, ABS, ■ Durability

foam board, coroplastic, metal etc.)

■ Double-layer print ■ High-gloss ink

■ Bright colors for graphics ■ White ink

■ Transparent print ■ Textured ink

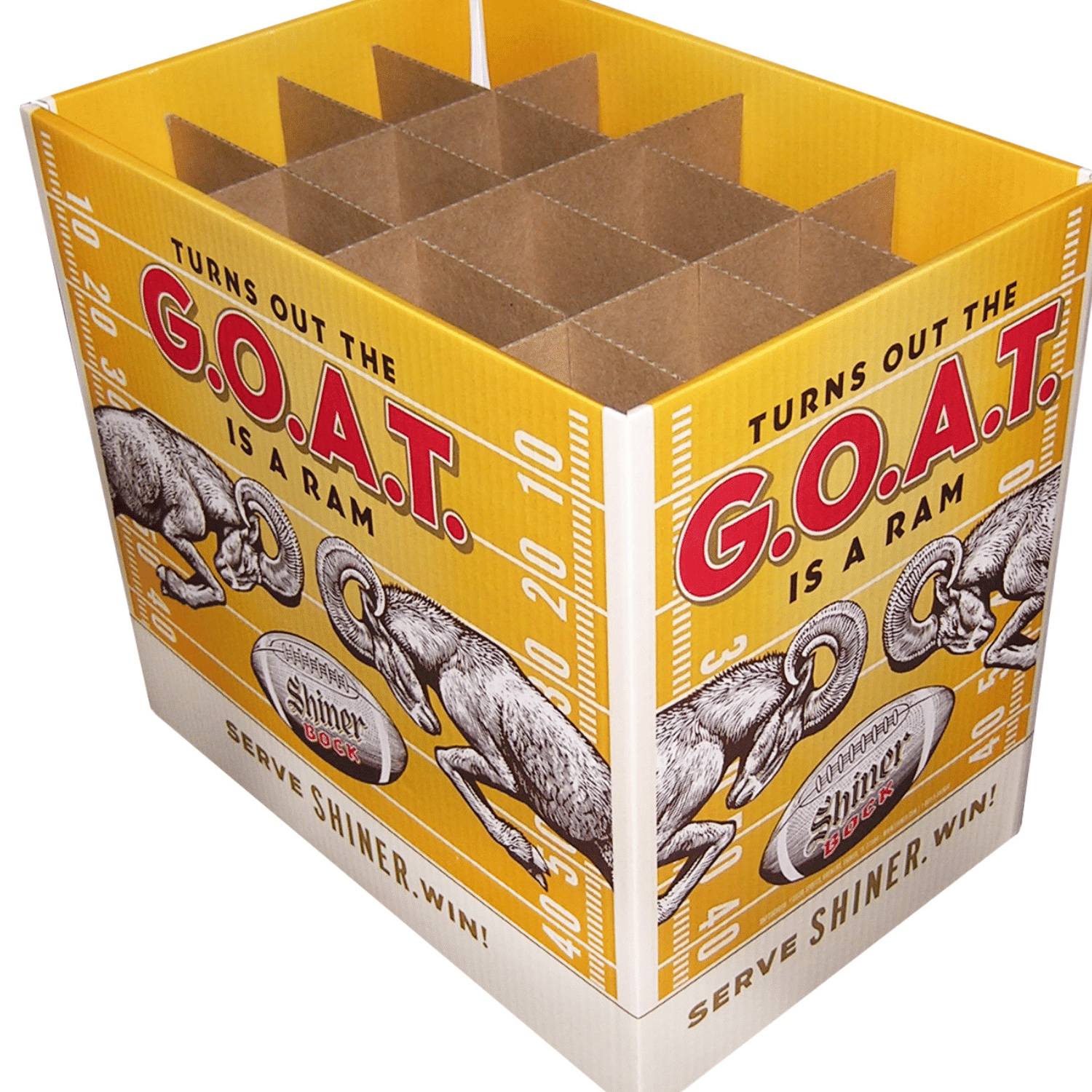

UV printers are super useful for all kinds of applications, from basic sign or gloss posters to more complex branding for specialty items and promotional products, including three-dimensional media. The possible applications of UV printers are limited only by the user’s creativity.

WHAT IS UV INK?

UV ink is a special type of ink that uses ultraviolet (UV) light to dry and cure. UV ink has existed since the 1970s but started to become more popular in the early 2000s as an efficient alternative to solvent-based inks.

UV ink has several benefits over solvent inks. UV ink doesn’t require a protective varnish. The chemical properties of the ink make it resistant to fading and water damage. UV ink also requires less energy to cure, so it can save you money on electricity.

When it comes to color depth and fidelity, UV ink is capable of sharper contrast and smaller color differentiation than solvent inks. Also, UV inks are highly stable and don’t require modification or thickening before use

Pros and Cons of UV Flatbed Printing■

UV printing machines have several advantages over other types of printer models and equipment.

PROS

Fast Printing

The UV lights cause the ink to polymerize and dry almost immediately, so you don’t have to wait for the ink to dry before binding, folding, or packaging. That means you can have more specialty items, including three-dimensional media, ready to go in a shorter amount of time.

More Flexible

Large-format UV flatbed printing machines are also more flexible than solvent ink printers. UV printing technology can print on a wide range of materials other than paper, such as acrylic, ABS plastic, foam board, and more. You can also make raised textures with UV ink.

Durable

Unlike solvent inks, UV inks are resistant to fading from sunlight and are scratch-resistant. You don’t have to worry about scuffs when transporting and handling your prints. UV inks also do not contain harmful solvents.

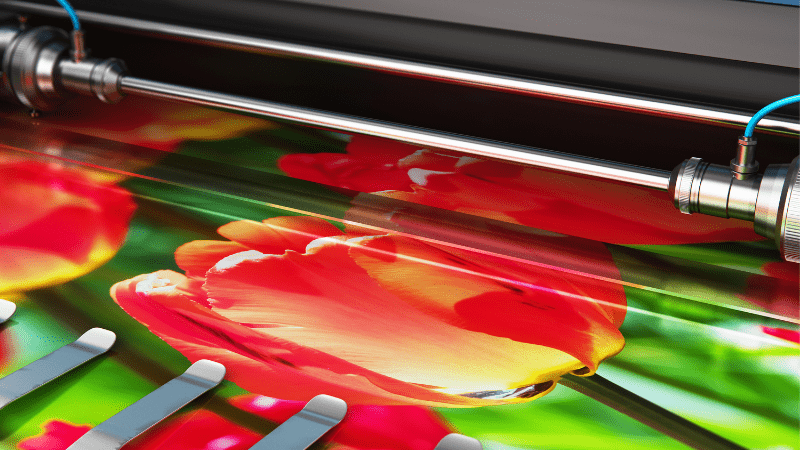

Better Image Quality

UV printing also produces higher-quality images. UV ink has smaller particles, and it dries quickly, so it does not smear and bleed into the substrate as much, The result is more vibrant colors and sharper image resolution, especially with black ink and white ink.

CONS

Price

Generally, a large-format UV printer is more expensive than its traditional counterparts. UV LEDs are also more expensive to replace than lasers. UV ink is more expensive, but a UV flatbed printer uses less ink per print than a solvent machine use.

Not Universal

Although they mesh with more substrates than solvent printers, a UV flatbed printer is much more difficult to use on some materials, such as ceramic or silicone. UV printing also does not work well with common textiles, so you can’t use it to print garments.

More Complex

Since it offers more options, a UV printer can have a steep learning curve when you’re starting out. UV printers make product customization easier to do on your own, but you will need to learn the software and understand how inks adhere to a range of surfaces.

Owning and Operating a UV Flatbed

Printer■

UV printing can increase your production speeds and contribute to further business development. Below are some of the most important aspects of owning and operating a flatbed printer.

SIZE

Arguably, the most important printer feature is size. Size determines printing area, so you need a machine large enough for your media graphics. The typical UV flatbed printer has a maximum printing area of around 30 square feet. A printer larger than 10 feet wide is called a grand format printer and carries a larger price tag.

PRICE

UV flatbed printers can come with substantial price tags. Prices depend on brand, size, and overall printing quality. Most businesses will not need to buy such a printer unless they frequently make in-house media and promotional materials. Print-on-demand services typically charge a flat rate per print job.

PRINTING PURPOSE

You also need to consider your actual printing goals. Do you need brand media like posters? Point of purchase displays? Large posters or signs? Your production goals determine the kind of printing substrate to choose and the size of the printing area you need. At KDM, we offer printing services for the following media types to help you support clients who demand customization:

■ POP displays ■ Coupons ■ In-house finishings

■ Flexographic printing ■ Murals ■ Window Clings

■ Vinyl graphics ■ Easels ■ Door decals

■ Aisle enhancers ■ Floor displays ■ And many more

■ Aluminum signs ■ Floor graphics

ALTERNATE PRINTING OPTIONS

A UV flatbed printer is excellent for all kinds of projects. However, sometimes a roll-to-roll printer is better suited. Roll-to-roll printing can use a wider variety of inks, but this technology also takes more time to print. Manufacturers create hybrid models with support for both flatbed and roll-to-roll options. However, these models can slow production if you switch between the two frequently.

Why Choose KDM?

KDM is your one-stop-shop for all your printing needs. We have over 50 years of experience serving as a retail marketing supply chain partner and have helped countless customers succeed. Our team features the unique services and the technology to help your business development and creative vision.

COST SAVINGS

We perform all on-demand printing services in-house, so we can offer competitive prices and quality performance. Our in-house services decrease market turnaround times, allowing you to react to trends faster when your clients demand customization.

SECURITY

Businesses trust us with their sensitive media documents. We take great care to keep your marketing materials secure and confidential. The only people privy to the final product will be you and your company.

CONTROL

At KDM, our clients have 100% control over their accounts. Our proprietary INTELLITRAK customer service system makes ordering and project customization and management simple. With store profiling intelligence and on-demand service, you can reduce time and management costs.

CONVENIENCE AND TIMING

Most importantly, KDM offers a reliable way to get your work done. We have quick turnaround times on print projects and can help create consistent brand messaging.

Affordable and Reliable UV Printing■

Flatbed UV printing is a great way to create vibrant, attractive designs for localized marketing strategies. If you want to learn more about our print services, contact us online or call us at (855) 232-7799 today to get started!

UV Flatbed Printing Portfolio■